The problem –

Electro-polishing is an electrochemical process, which is performed in a bath of acidic electrolyte. The energy is provided by a rectifier.

The metal piece is connected to the positive terminal (anode) and the negative terminal is attached to an auxiliary electrode (cathode).

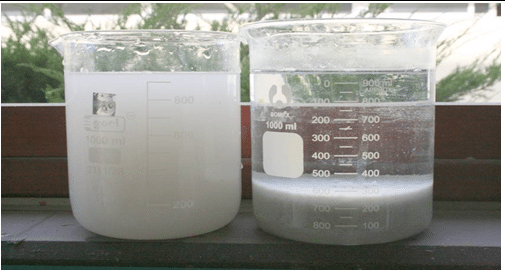

During this process, a layer of some 20 micron is removed and the wash water contains high concentrations of heavy metals. Its discharge to the municipal sewer is forbidden.

The solution

SWDP LTD. developed and implemented a unique technology for the removal of heavy metals from wastewater of metal coating plants.

The treatment uses aluminate salts (sodium and potassium).

Results

The electro-polishing plant has been operating for more than 10 years with treated wastewater meeting the stringent requirements of the authorities.

The process enables:

Effective removal of most heavy metals including: Cobalt (Co), Copper (Cu), Manganese (Mn), Lead (Pb), Zinc (Zn), Tin (Sn), Vanadium (V), Chromium (Cr) and Nickel (Ni).

Effective removal of Phosphorus and Fluoride.

Neutral pH of wastewater after treatment (6.5-7).

The process is generally cheaper than alternative technologies and relatively easy to apply.

You'll be interested: הכדורים הטובים ביותר להזקפה