The problem –

In Israel, there is a large number of poultry processing plants.

Wastewaters from poultry plants are generally treated in Dissolved Air Flotation units (DAF).

Salt containing wastewater is treated separately.

The salt containing (Kosher) part of the treated wastewater has to be dumped in the sea.

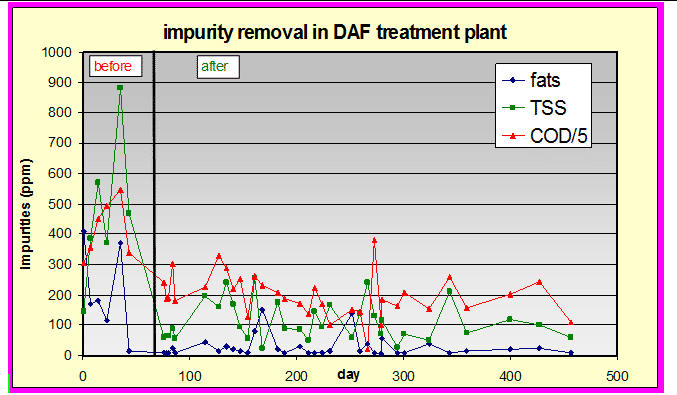

Authorities set high standards for the removal of suspended solids (TSS), fats and organic compounds (COD) mainly for the salt containing wastewater.

The quantity of waste water sent to the sewer is high and monitored by the authorities.

The removal of the “salted” waste to the sea requires highly efficient removal (NTU < 50.) which requires high chemical consumption in the DAF.

The usual treatment based on Aluminum Sulfate and Caustic Soda is expensive.

The solution

SWDP LTD. proposed to replace Aluminum Sulfate (Ferric Chloride) with pH correction by Caustic Soda by using Sodium Aluminate.

Results

SWDP LTD. has followed up the performance of several plants during many years. The quality of the treated water was excellent and steady.

Fats measurements were generally below detection level.

Salts' addition in the treated water was significantly lower (salinity is a problem for reuse of the treated wastewater).

The cost of chemicals per m3 waste was significantly lower when Sodium Aluminate was used. Saving of 30% and more have been measured in several plants.

Monitoring of improved performance of a DAF by using Sodium Aluminate